The Rotor Spray system, manufactured by Ahlbrandt - A Baldwin Technology Company, offers an effective solution for uniformly applying liquids to papers, films and fabrics on web lines.

Rotor Spray is most frequently used to apply anti-fog, anti-static and similar solutions to films as part of extrusion lines.

How It Works:

Ahlbrandt’s Rotor Spray™ application system uses rotary disks to achieve even, uniform coating of process liquids onto films - coatings and chemicals can be applied to one or both sides of the film, and different liquids can be used on each side of the web, for applications that require this.

Each Rotor Spray system has a 60-liter tank that feeds the lines to the rotary heads/discs; excess liquids are reciculated back into the tank, enabling near-zero waste of chemicals during the production process.

Systems are simple to operate, offer low maintenance costs, and are available in spray widths as wide as 5500mm. The precise spray helps operators save chemicals and drying time while achieving highly cosistent dosing that is flexible and easy to adjust, and is uniform across the substrate.

A key benefit of Ahlbrandt’s Rotor Spray system is its ability to apply coatings very thin: chemistries can be accurately sprayed 10 to 1000nm thick.

Noteworthy Benefits:

Allows for the application of anti-fog chemicals, release agents, anti-static coatings and more to films, increasing film value

Systems are easy to operate and require minimal maintenance - servicing is easy

Units can be built for webs up to 5500mm wide

Precision spray achieves consistent dosing and reduces drying time

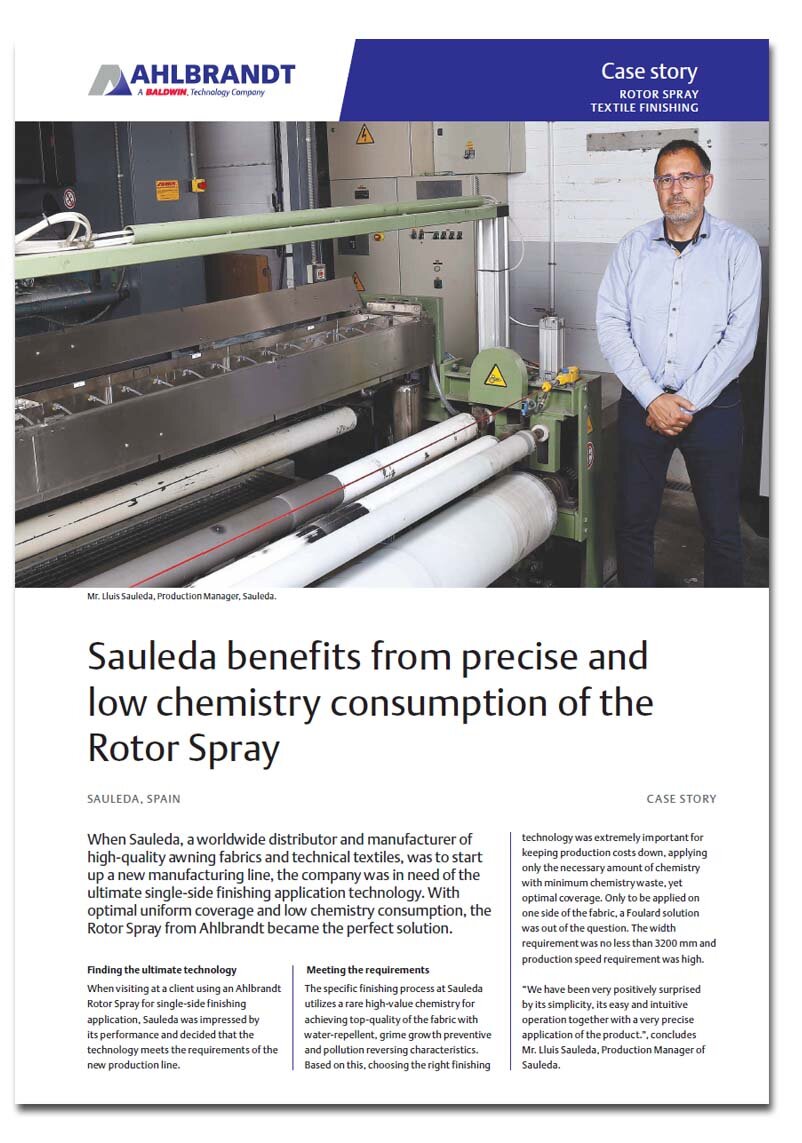

How to benefit from the precise and low chemistry consumption of the Rotor Spray

Read the real-life success story of a Rotor Spray installation at the Spanish Textile manufacturer Sauleda. Click here to read further!

Free Webinar:

How to Deliver Automation and Productivity in Film Extrusion

• Operator safety • Process efficiency • Energy consumption • Quality consistency

How to implement optimal chill & cast cylinder cleaning and surface treatment in cast film extrusion, plastic sheet extrusion and blown film extrusion.